Choosing and purchasing a manicure tool is only half the battle, since it requires constant and high-quality maintenance and sharpening. New scissors or forceps can become dull after just a few uses, and some need to be brought into good working condition immediately after purchase. It all depends on the quality of the metal and the initial characteristics of the tool. What does a manicurist need to know about sharpening manicure tools? Is it possible and how to sharpen nail scissors, tongs and cutters at home? How to evaluate and accept a job in the service? Let's look at all the questions in order.

Rules of care

For manicure accessories to last a long time, they need to be well cared for. It is very important to store your tools correctly. Most often, they become unusable precisely because of improper storage.

Regular and timely care of manicure accessories will ensure their comfortable use and long service life.

- Scissors, wire cutters and tweezers must be stored in special cases , otherwise notches and unevenness may form on their surface. If you don't have a special case, you can wrap them in soft cloth.

- Do not store manicure accessories next to each other , avoid sudden temperature changes and high humidity.

- Place all cutting tools with the blade facing up or on its side .

- Scissors and wire cutters should be oiled .

How to sharpen nail clippers and scissors without a machine

Nippers, tweezers, and scissors are among those tools in the manicure set, without which it is difficult to imagine performing a perfect trimmed manicure or pedicure at home. The blades of each tool must be sharp, smooth, without gaps in order to efficiently and safely remove the keratinized layer of the cuticle and give the free edge of the nail plate the desired shape. Even professional manicure tools from well-known brands after a while begin to tear off pieces instead of cutting the nails/cuticles evenly. And cutting tools from regular manicure/pedicure kits must be sharpened immediately after purchase.

There are three options to solve this problem. Firstly , you can use the services of an individual sharpener who comes to the client’s home and polishes the cutting parts of nippers, tweezers and scissors manually. As a rule, the master works with a diamond monolayer (with a continuous diamond layer) whetstone. Secondly , you can go to a workshop where a certified specialist will professionally sharpen manicure tools using a diamond wheel or in a special machine. In this case, the services will cost more, but the company provides a guarantee for its work (service life of at least 6-7 months, even with frequent use). Thirdly , you can turn to the “strong half” of your family for help and sharpening manicure tools at home will save your family budget. You will learn how to properly sharpen scissors and clippers for manicure/pedicure from the photo and video materials in this article. ♦ SHARPENING NAIL CLIPPERS AT HOME You can sharpen the blades of the clippers using a regular carbon steel file. Choose a file with a uniform grain and close-fitting, fine cuts. We recommend 'experimenting' with old nail clippers, and if you have an expensive professional tool, it is best to seek help from an experienced specialist.

Your recommendations will be very useful to all site visitors! Please leave comments on the article, share with each other the secrets of home care for manicure tools. If you want to post your photos and video materials on the topic on the site, please write a message to us by email: This e-mail address is being protected from spambots. You need JavaScript enabled to view it. To the main page

ALSO FIND OUT...

| Comments | Add new | Search |

Children's Portal: Home Page

3.26 Copyright (C) 2008 Compojoom.com / Copyright (C) 2007 Alain Georgette / Copyright (C) 2006 Frantisek Hliva. All rights reserved."

Related materials:

- It's no secret that with the help of a haircut you can visually increase the volume of your hair and make the appearance of your hairstyle noticeably more impressive and fresh. By the way...

">Thermal haircut for sealing the ends of split ends

- A variety of foot care methods allows us to choose the best option for procedures and often eliminates the need for regular visits to the…

">Pedicure machine for removing dead skin on heels

- Classic (trimmed) manicure is a traditional way of caring for natural nails using manicure tools. Unlike the procedure e...

“>How to do edged manicure at home (photo, video)

- Hygienic manicure is not only the ability to cut your fingernails correctly, but also regularly maintaining the impeccable appearance of your fingers using…

“>How to do a hygienic manicure. Video lessons and photo instructions

- What is a nail clipper and is it worth adding this tool to your manicure set, the popularity of which has noticeably increased recently?…

">Large and miniature nail clippers for newborns

The following materials:

- Why are professional cuticle files in high demand and is it worth expanding the arsenal of your manicure set with this sufficient...

">Laser and ceramic files with diamond coating for cuticles

- Bafik is a convenient manicure tool for polishing natural nails to a pearlescent shine, made in the form of a rectangular bar with a...

">How to use polishing buff for natural nails

- Fingers with an overgrown film of pterygium on the nail plates and keratinized layers of cuticle with hangnails do not look very neat, to put it mildly...

">Professional tweezers for home manicure and pedicure

- Nippers are rightfully one of the most important tools for high-quality home manicure and pedicure. It's hard to imagine leveling...

">Nippers for manicure/pedicure. Correction of cuticles and ingrown nails

- To perform a hygienic manicure, it is useful to have a set of special scissors on hand to maintain the well-groomed appearance of your nails without…

">Good scissors for manicure and pedicure

Previous materials:

- In order for our fingers to always look well-groomed and beautiful, it is enough to devote 30-40 minutes a week to a hygienic manicure. And classic...

">Professional tools for manicure and pedicure

- To perform modern modeling and fashionable nail design, we use special equipment, reliable manicure tools and materials...

">Vacuum hood for manicure table

- To enjoy the look of beautiful nails, you need to constantly care for them and adjust their shape using manicure and pedicure tools. ...

">UV and glasperlene sterilizers, dry heat cabinets for manicure

- Nails painted with gel polish look incomparable and the damage-resistant coating allows you to maintain a fashionable manicure for several…

">LED or UV lamp 36 W for drying gel polish and nail extensions

- If you like to do your own manicure at home, if you constantly follow the latest nail designs and implement interesting ideas...

“>Choosing a manicure table. Photo options and tips

- Manicure files for correcting the length of nails and the shape of the free edge differ in appearance, degree of hardness (abrasiveness), material made...

">Manicure files for polishing and grinding nails

Signs of a dull instrument

Typically, a blunt tool has jagged edges; sometimes of scissors and wire cutters differ The tips and cutting edges become so thick that it is almost impossible to grip the skin or remove an ingrown toenail.

The frequency of sharpening depends on how often you use the manicure set. Usually the need for it occurs once every 2-6 months .

This video will tell you how to sharpen nail clippers:

Tips for using the tool

In order for the manicure set to last as long as possible without the need for repairs, the following important rules should be taken into account during its operation:

- store all tools in separate protective cases;

- never wash them with plain water;

- clean after each use with special products;

- periodically lubricate moving parts with oil;

- use tools strictly for their intended purpose.

The last rule says that nail clippers will need sharpening much earlier if they are intended for cuticles and are used to remove nails, and vice versa.

Each tool has its own function, performing which it brings maximum benefits for the beauty of the handles.

Signs of a well-sharpened tool

- Cuts the nail plate, rough skin and cuticle smoothly, with the entire blade, but especially well at the tips.

- Cuts in a thin layer.

- Causes deep deformations.

- Does not tear or pull the skin.

- It runs smoothly and cuts well without pressure.

Appearance of a well-sharpened tool

- The working blades are free from nicks, scratches and stains;

- the tips of the scissors and nippers are thin and equal in length and width;

- the cutting blade is uniform and has no sharp breaks;

- when closed, the cutting blades do not intersect.

How to check the quality of sharpening and sharpness of tools

It’s easy to verify the quality of sharpening. Use a piece of cloth to test the scissors. Stretch it in your hand and cut it - the medium should be smooth, even, without jagged edges or torn edges. A piece of napkin or plastic film will help you check the wire cutters. Remember - the nose of the tool should not catch the material, pull threads from the fabric, or fibers from any materials.

Correctly and efficiently sharpened manicure tools will be the key to the popularity of your services among clients. Sharp scissors, nippers and scrapers will help avoid skin injury, provide comfortable nail care, and make manicure a truly enjoyable procedure. Don't forget to sharpen your tool in a timely manner and update it if necessary. Buy quality products that can be sterilized and processed without losing their strength.

Sharpening accessories

You can sharpen manicure accessories in a special workshop or yourself. To do this, you can use a regular fine-grained whetstone or machine . It is advisable to use a diamond-coated grinding wheel . You can buy it at any hardware store or rent it.

You can also use sandpaper . This option will provide a softer and faster sharpening, and it is much simpler than the others. However, such sharpening is short-lived and requires more frequent repetition.

If scissors have curved blades, it is almost impossible to sharpen them yourself. You can only tighten the connecting bolt, and it is better to entrust sharpening to professionals.

To sharpen efficiently, you can take special courses or master classes. It is also advisable to undergo training if you often use manicure tools and they require constant care and sharpening.

Tool Features

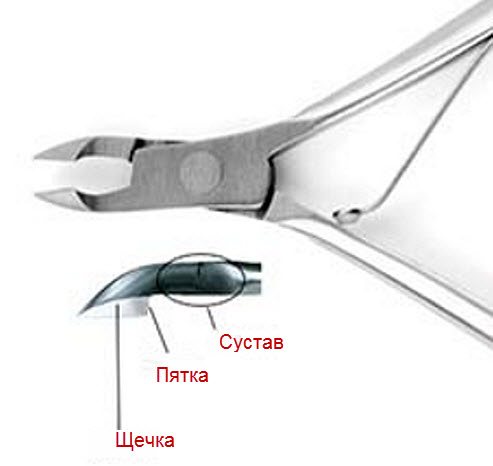

To give a second life to your manicure set, you need to correctly classify it and determine the tools necessary for this. Thus, manual sharpening of nail clippers and tweezers is most often carried out using a needle file, since their cutting blades have a curved shape. If a backlash is formed when they are compressed, then the repair is also supplemented by adjusting the connecting bolt.

After sharpening, the master must polish the tool to smooth out the slightest irregularities and treat everything with a disinfectant.

Types of sharpening

There are different types of sharpening: mechanical and diamond, manual and professional.

Diamond

During factory diamond sharpening, parameters such as sharpness, ideal angles, and convergence of cutting edges are taken into account. This technology allows you to sharpen products that have denser metal in the cutting part, making them more durable and sharp. This sharpening can last for more than a year in home use.

Mechanical

Mechanical sharpening is carried out using mechanical machines. In this case, the master processes each tool manually, giving the necessary sharpening angles, controlling the entire process exclusively by hand. This type of sharpening is simpler and less durable.

Get acquainted with the author's sharpening technology:

Basic rules for sharpening tools

There are several key points that make up the algorithm for servicing manicure equipment. If all points are completed, we get the desired result.

- When closing scissors, forceps or cutters, nothing should prevent the handles from coming together. If such a problem arises during work, they must be taken to the workshop and all interfering or protruding parts must be ground off on the machine. At home, you can do this with a sharpening stone or rasp, being careful.

- Nippers, cutters and scissors should not dangle, there should be no gap between the cutting planes and at the point of connection of the handles.

- The cutting planes of the nippers should be smooth and close without gaps under gentle pressure.

- The convergence of the cutting edges in the nippers should be uniform from one edge to the other, and not wavy: first the tip, and then the heel, or vice versa.

- The blades should not have protrusions or burrs that catch, scratch or cut the skin.

- The outer edge of the pusher should be sharper than the inner one, and the inner one should have a straight line without jagged edges. The main task of the tool is to move the skin, not cut it.

When sharpening, all factors must be met to obtain the desired result.

Sharpening of pliers, skin tongs, tweezers. If the cutters are loose, they are stuffed at the junction of the blades. They should walk softly and close in an even line. The inside of the nippers is ground down to a straight line from the inside. When closing, the blades should be in the same plane, neither higher nor lower than one another. If there are burrs on the tips of the cutters, they need to be sanded down.

Nippers for manicure and pedicure - types, brands, selection criteria and operating rules

Sharpening pushers.

After processing, they should be sharp, but not cut the skin. They should also not scratch the nail. If the pusher falls and bends, the edge is leveled and then ground down. The pusher is always sharpened on the outside, and only polished on the inside. It is necessary to ensure that the outer edges are not sharp; they should also be ground and sanded.

Types of pushers - comparison, characteristics, operating rules

Sharpening nail scissors.

If the blades were deformed after a fall, the edge will have to be ground down. If the damage is significant, then most often the scissors cannot be repaired. If the deformation is small, then grinding helps eliminate it, but the length of the blades will be reduced.

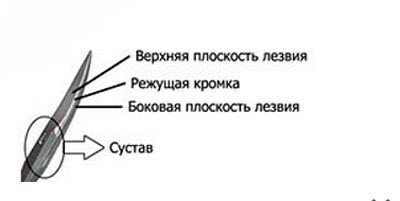

When sharpening scissors, only the front surface is removed. You cannot go into the rear one; it was processed only once at the factory, and this is enough for the entire operating cycle. After each grinding of a layer, it is necessary to remove the metal grain from the blades so as not to damage them when closing.

Nail scissors - types, proper use, choosing the best

The sharpening angle of the scissors must correspond to the factory rake angle and cannot be changed. Usually it is 60-75°.

At the final stage, it is recommended to go over the blades with fine-grained sandpaper to remove burrs.

Sharpening manicure knives.

They are used mainly for pedicures, to remove rough skin and corns. The manicure knife should not be very sharp; the factory angle should be maintained and the edge should not be ground into a bayonet.

How to prepare manicure tools for repair

Before you sharpen a manicure tool, you need to make sure that the problem is in the sharpening and prepare it properly.

Carefully inspect the tool for the presence of center play in the scissors; the axle mount may have become loose. Typically, the axle is a screw or rivet. If a bolt is used, tighten it.

If the screw is already tightened and the blades are still hanging loose, do not bend the blades under any circumstances. This can be corrected by sharpening the limiter, this will allow the blades to be brought closer to each other. Even new cutters sometimes have some play initially. If it is not removed, there will be no correct pressure on the cutting edges, as a result of which the nippers will leave burrs and make poor cuts.

Useful tips

Recommendations:

- Inexpensive tools do not need to be taken apart. Poor quality fasteners may not withstand being disconnected and reconnected.

- When working with a sharpening machine, it is necessary to set low speed. High rotation speed will damage the cutting edge.

- After purchasing a tool, you need to remember its angle. It must be adhered to during sharpening.

- If you need to sharpen professional manicure tools, it is advisable to use the services of professionals. Carrying out the procedure yourself requires practical experience. To do this, you can practice on old instruments.

- Wear safety glasses when operating the sharpening machine.

- Bars less than 8000 grit are used to smooth out serious damage and chips. If there are no such problems, you should not choose stones less than 8000 grit.

- Do not forget about regular lubrication of moving elements with oil (machine oil, vegetable oil).

- Store tools in a dry case without access to moisture. Constant moisture will cause rust to form.

- After work, clean tweezers, scissors, files, tweezers from dirt and debris.

- A simple option to restore the sharpness of nail scissors is to cut the foil. The sharper the blades are needed, the more cuts required.

It is strictly forbidden to change the angle of the cutting edges, which was made by the manufacturer.

Sharpening manicure instruments is a responsible procedure that will help restore sharpness and perform work more efficiently. However, in order not to permanently spoil the cutting edges, it is necessary to take into account a number of nuances and recommendations of professionals. If it is not possible to spend enough time for sharpening, you need to contact a specialized workshop.

Sharpening at home

Having everything you need, you can sharpen your tools yourself. To do this you need a sharpening stone, sandpaper, and lint-free wipes .

Place the sharpening stone on a flat surface, open the nail scissors or tongs wide and begin sharpening. Movements should be smooth, even, and there is no need to sharpen for a long time. After completing the procedure, the instrument should be wiped with a soft cloth.

The sharpness is checked on a piece of polyethylene: if the tool is well sharpened, the polyethylene should not wrinkle when cut.

It is best to have a sharpening machine with a diamond wheel, which will make your task much easier and keep the tool sharp much longer than sharpening on paper or a whetstone. But such an expensive purchase is only advisable if you do manicure professionally.

How and with what to check the sharpening level

Even a professional manicure cannot be done with a blunt instrument. That is why regular maintenance of tongs, scissors, and tweezers is necessary. With a large flow of clients in the salon, maintenance of scissors and cutters may be required once every two to three weeks. With a lower flow - much less often.

To understand when it's time to sharpen your manicure tools, there are a number of simple tests. They will require the following materials to choose from:

- Thin plastic bag

- Stretch film

- Dried wet wipe made of non-woven material

- Elastic vinyl, latex or nitrile gloves

These same tests will allow you to check the quality of the work performed by the master. In the workshop, these tests are used to check each of the processing stages of blades and cutting edges.

Methods and instructions on how to check the quality and level of sharpening:

- We fix the thin plastic bag so that the edge is even. Unclench the scissors, tongs or wire cutters, place the edge of the bag between them, and close along the entire length. The blades should not tear, snag or pull the polyethylene.

- Stretch film is the most demanding material for checking the level of sharpening. The principle is the same - we fix the film and close the blades along its entire length. The cut should be smooth.

- A napkin made of non-woven material demonstrates well the presence of burrs on metal. With high-quality processing, the cut is smooth, without snagging on the blade.

- Vinyl or nitrile gloves should be secured between the thumb and forefinger, the cutting edges should be completely opened and closed, placing the glove sheet between the blades, and then pulled down slightly towards you. Often scissors or tongs cut well at the base, but the closed edge pulls the glove and tears it. This means it's time to sharpen the blades again.