Disinfection is the prevention of infectious diseases. This is a system of measures to destroy pathogenic microorganisms, their spores and the toxins they secrete. Disinfection is one of the stages of instrument processing, and under no circumstances should it be skipped.

All parasites are distinguished by their fertility and ability to mutate. There are a lot of infections around us. They are developing at tremendous speed. If the rules for handling instruments are violated, the client’s health can be harmed.

The safety of you and your clients must come first.

Which disinfectant to choose?

There are different options: you were recommended by a master with experience, a teacher for training, or someone praised you on the Internet. There are about 250 types of disinfectants on the market, and choosing the best one can sometimes be difficult. Disinfectants differ in chemical and physical properties, antimicrobial activity, and toxicity. Chlorine-containing products have a very active odor - this option is not entirely suitable for salons where clients and yourself are located. Pay attention to the areas in which it is recommended to use the product, as some are intended for medical institutions. We also do not recommend saving on disinfectants and buying the cheapest ones - you can ruin your instrument.

Disinfection and sterilization are a necessity. The main provisions are described in the following documents:

— Constitution of the Russian Federation Art. 41

— Federal Law-52 “On the sanitary and epidemiological welfare of the population” Art. 2, paragraph 1

— SanPiN-2.1.2.2631-10 clause 9.22, 9.24

— OST 42-21-2-85 “Sterilization and disinfection of medical devices. Methods, means and modes."

— MU 281-113 “Guidelines for disinfection, pre-sterilization cleaning and sterilization of medical devices.

All processing of instruments is carried out in three stages: Disinfection, PSO, Sterilization. Sterilization cannot be carried out without disinfection and PSO (pre-sterilization treatment).

Disinfection can be carried out in several ways: irrigation, wiping and soaking. Depending on the object being processed.

All tools and consumables must be processed. It is important to remember that disinfection and sterilization must be carried out with complete immersion (!) of the instrument and material in a disinfector or sterilizer (metal instruments).

In order to carry out disinfection, we need a disinfectant. There is a difference between a disinfectant and a disinfectant. solution. The solution is what we already prepare ourselves. A novice master most often gets lost in choosing the right disinfectant.

Types of disinfectants

When choosing a disinfectant, you need to understand what options are available. It can be sold as:

- concentrate;

- powder for further mixing with water;

- ready solution.

The third option is less economical. The product can also combine the capabilities of processing instruments at different stages of the sterilization process, namely:

- Suitable for both disinfection and chemical sterilization : in different preparation concentrations and with different holding times;

Chemical sterilization of manicure instruments: rules according to SanPiN - Combine the possibility of disinfection with pre-sterilization cleaning (the composition contains detergents).

This is important when working with ultrasonic washers. Disinfection and pre-sterilization cleaning of manicure instruments: how to choose a disinfectant and prepare the solution correctly

Criteria for choosing a disinfectant:

1. Water index (PH) must be less than 8.5 units.

2. Must have cleaning properties.

3. Exposure 15 minutes

4. Should be universal in concentration 5. Should not require rotation (replacement) 6. Should not cause metal corrosion.

1. If PH is more than 8.5 units, it is necessary to conduct a phenolphthalein test at the PSO stage. This test shows residues of detergents on the surface of the instrument.

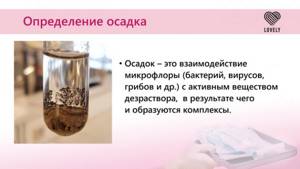

2. When interacting with a disinfectant, all pathogens, viruses, bacteria and fungi form complexes - they settle on the surface. In fact, after disinfection they are already safe, but we must definitely remove them. And this must be removed mechanically - either with a brush or in an ultrasonic cleaner, depending on how you clean (manual or mechanized). Modern disinfection solutions often have both properties - they both disinfect and wash. The convenience is obvious: one container with a solution - you soak it in it, maintain the required exposure time, and then use the same solution to clean the surface of the instrument with a brush. You don't have to take anything out, carry it, soak it in another container of detergent, and rinse it. You save time and money.

3. Exposure – the time the instrument is kept in the disinfectant solution. There are different times: 15 minutes, 20 minutes, 30 minutes and even an hour. Ideally, the master should have three sets of tools at the request of SanPin: the first in work, the second in processing, the third ready to be replaced for another client or for replacement. For a novice master, it can be expensive to purchase three sets, so you can choose a disinfectant with the lowest exposure. After seeing the client off, you must disinfect and sterilize the instrument, treat the area and meet the client - this is just an average of 15 minutes. The more often an instrument is exposed to a disinfectant solution, the shorter the instrument’s lifespan. The time is specified in the instructions.

4. Concentration. Under no circumstances should we spray the composition onto instruments. Because all surfaces, locking parts and hard-to-reach places must be treated. This is only possible with complete immersion. Ideally, you treat both the tools and the work surface with one concentration of the solution - this saves you time and money, and you will not mix up the containers and will be confident in the safety of use. Whenever preparing a disinfectant solution, it is necessary to control the concentration.

5. All pathogenic microflora: viruses, fungi, bacteria adapt perfectly to various disinfectants. Therefore, it is very good if your product does not require rotation (replacement). After about three months, some products need to be changed. For example, “Optimax prof” needs to be changed, for example, to “Optimax intro”. This information is also included in the main instructions.

6. Damage to metal. Any processing spoils the instrument, but this cannot be avoided. Carefully look at the composition of the product, it can be very aggressive. There may even be plaque on ceramic cutters.

To choose a product for yourself, you can use the table on surface disinfection modes for viral infections. It is necessary to decide on the parameters: type of objects being processed, type of processing, concentration, exposure and processing method. Also pay attention to the smell, color, and ease of breeding. The choice of disinfectant is individual, as each master has his own personal preferences. Check the shelf life of the finished solution: usually the solution is good for about 2 weeks.

Alaminol and disinfection of manicure instruments: pros and cons

Alaminol is most often used to disinfect manicure instruments, since this antiseptic:

- sold in any pharmacy;

- intended, among other things, for use in medical institutions, that is, it is quite safe and reliable;

- effective against bacteria, many viruses and molds;

- does not cause rust on metal;

- The concentrate is stored for up to 2 years, and the finished solution – for up to 10 days.

It also has disadvantages:

- in case of contact with skin, may cause burning and redness;

- The disinfection procedure lasts 60 minutes.

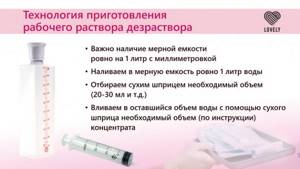

How to breed

Alaminol should be diluted to a 5% concentration. That is, you need to take 50 ml of the product purchased at the pharmacy and add 950 ml of warm water to it. This will result in a large volume that most likely will not be able to be used at one time. Therefore, it is better to take 25 ml of Alaminol and dilute 475 ml of water. The latter must be heated to at least 18 degrees.

How to dilute the solution?

A common mistake made by the technician is that the solution is not diluted according to the instructions. Making it stronger doesn't mean you'll do better. Everything is written in detail in the table above. All instructions on how to dilute disinfectants are included when purchasing products and must be carefully studied.

Dilution must be carried out wearing gloves and a mask.

Main stages

It is necessary to disinfect and sterilize instruments in a certain sequence. The whole process takes quite a long time, so every manicurist is required to have several sets of tools per shift. So:

- After you have completed the manicure procedure, all used tools should be thoroughly washed in running water and soap, removing visible dirt;

- Next, they are placed in a tray with a disinfectant liquid and kept in it for a certain time;

- Disinfected instruments are placed in a sterilizer. There they undergo global treatment against all harmful microorganisms;

- After this, the already sterile accessories are packaged and packed in sealed bags to maintain their purity;

- Immediately before the next procedure with the client, the package is opened and the instruments are again treated with alcohol or a disinfectant solution.

When is it necessary to replace the disinfectant solution?

There are 4 states of solution deterioration:

— the expiration date has expired;

- the color of the solution has changed;

— turbidity of the solution appeared;

- flakes and sediment appeared.

After such conditions appear, the solution must be replaced, even if the expiration date has not expired.

What documents should there be?

For disinfectants you need: a registration certificate and basic instructions. You must ask for them in the places where you purchase disinfectants. You don't need to request it all the time if you use the same tool. If you were not provided with it or you forgot to ask, you can find it on the Internet. If you have a check at the salon, this document must be available.

In the document you will find information such as the concentration of the product and much more.

Treat your tools according to all the rules, and your clients will appreciate it!

Manicure instruments disinfection log: where to get it, how to fill it out

In a salon or studio, an officially working master must have a log of disinfection of manicure instruments, or rather quality control of solutions, which indicates:

- dates of filling and preparation of the mixture;

- its purpose (disinfection) and name;

- volume of prepared substance;

- its concentration (required by SanPiN and real);

- method of analyzing a solution to determine the indicator from the previous paragraph (equipment or test strips);

- data from the person who carried out the analysis.

The control organization monitors the cleanliness of cutters, scissors, files, and wire cutters using a document regarding the receipt and expenditure of disinfectants. To fill out this type of journal for the disinfection of manicure instruments, you must indicate:

- in the first table - the name of the concentrate, date of purchase, quantity, expiration date, name of the person who purchased it;

- in the second - the date, the object of disinfection (instruments), the name of the product and its concentration, the amount used, the name of the person responsible for the procedure.

You can buy both magazines in many online stores. Some people download them online and print them out. The pages in both cases must be bound and numbered. All information is entered by hand.