Careful treatment of manicure tools is a conscious necessity on which the health of the master and clients depends. A frivolous attitude to this rule can provoke unpleasant consequences - from inflammation, fungi and mycoses to infection with very dangerous infections such as hepatitis C and HIV.

Do not underestimate the risks, because manicure accessories, along with particles of nails and skin, contain numerous microorganisms, bacteria and viruses. The slightest scratch or wound is enough for them to penetrate the body. Therefore, when it comes to disinfection and sterilization of instruments, it is better to be neat and even perfectionists.

Treating hands with antiseptic

Before performing a manicure, you must disinfect your hands and the client’s with a disinfectant. To do this, you can use the following antiseptics: Neosteril, Octenisept, Bacillol, Sterillium, Kutasept F, Eco-breeze. They come either in sprays or in containers with dispensers.

The product is applied to dry hands and distributed evenly over the skin. It is important to carefully work on the inside and back of the hands, the areas between the fingers and around the nails. After this, it is recommended to wear disposable latex or rubber gloves.

Next, the client’s hands are treated with an antiseptic. Use hand sanitizer twice if there is a risk of contracting hepatitis B or tuberculosis.

Recommendations for antiseptic treatment

- The antiseptic is taken from the dispenser into the recess of the palm

- Nails should be clean and cut short

- When working, it is necessary to remove rings, bracelets, watches

- When applying antiseptic, the skin of your hands must be dry.

- It is recommended to use an antiseptic with components to restore the lipid layer so that the skin does not dry out excessively and is less susceptible to injury and cracking.

- The antiseptic is rubbed into the skin of the hands until completely dry.

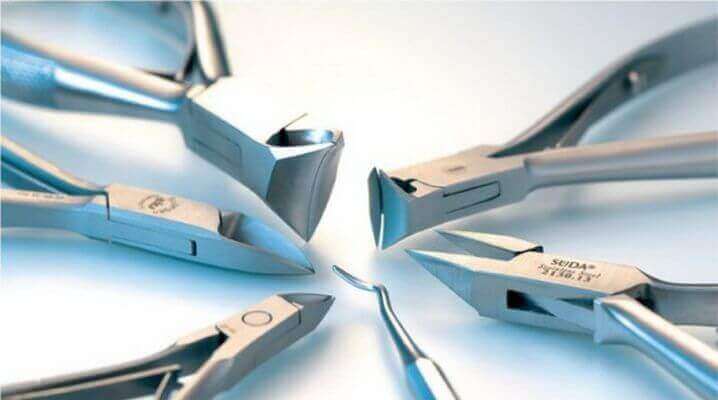

Disinfection of manicure instruments - the first stage of treatment

Disinfection is the destruction of bacteria, viruses, fungi and any other microorganisms from working manicure tools and surfaces. It is the first stage of processing. There are three of them: disinfection , pre-sterilization cleaning and the final one – sterilization .

For disinfection in salons and when professionals work at home, a chemical method is used. It is based on the use of special disinfectants in the form of solutions, tablets, and aerosols.

They should have a wide spectrum of effects, which includes antifungal and antiviral effects. The products can be purchased ready-made, or the concentrate can be diluted in the specified ratio.

The ratio is different for each disinfectant, so you must follow the instructions or recommendations of SanPiN. Good disinfection liquids should contain anti-corrosion additives.

Containers with ready-made and prepared solutions must have lids and stickers with the name of the disinfectant, concentration and date of preparation during storage.

Each salon or home technician chooses for himself which disinfectant to use. There is also a list of drugs recommended by SanPiN.

Features and choice of ultrasonic washing in a beauty or manicure salon

RULES FOR DISPOSAL OF BLADES

In modern practice, leading nail service specialists do not recommend the use of disposable blades for pedicures, but many nail technicians still use this technique.

Disposable razor blades are immersed for disinfection and further disposal in a special container filled with 1% Estilodez working solution. We replace containers daily at the end of the work shift.

Watch the video where we explain in detail and show all the stages of processing tools in the nail service room.

The material was prepared by the Chistovye brand, an expert in the field of disinfection, sterilization and a manufacturer of disposable consumables for the beauty industry.

Means for disinfecting manicure instruments when working at home and in beauty salons

After performing a manicure or pedicure, disinfection is the first stage of treatment. Let's look at the most popular options for disinfectant solutions and concentrates. The higher the price of the product, the safer the composition for metal tools is considered.

Before disinfection, all instruments or devices are opened, complex mechanisms are untwisted and immersed in the solution.

It is necessary to ensure that there are no air bubbles or voids left on the surfaces that would prevent the penetration of the product.

Gigasept AF – intended for disinfection of manicure and medical instruments. The prepared solution can be used within 7 days. If it changes color, you need to prepare a new one and discard this one.

Gigasept AF can also be used for pre-sterilization cleaning, the second stage of processing. In this case, after soaking the equipment in the solution, it is enough to rinse it under running water for 10 minutes and additionally immerse it in distilled water for 1 minute. Instruments must be completely dry before sterilization.

Korzolex Plus - can also be used for two stages, disinfection and cleaning before sterilization. The untwisted instruments are lowered into the solution prepared according to the instructions, and the recommended disinfection time is maintained. Then cleaning with a brush is carried out in hard-to-reach places and rinsing with running and distilled water.

After preparation, the solution is recommended for use for no more than 5 days. Both the first and second products can be used in ultrasonic washing baths with metal containers.

Alaminol is a broad-spectrum disinfectant concentrate. The finished solution can be used for no more than 10 days or until the appearance changes. Suitable for use in ultrasonic installations. Dilute strictly according to the instructions, wearing gloves.

Details about choosing a disinfectant:

How to choose a disinfectant, review of the best

Using disposable nail files

Rospotrebnadzor recommends using disposable manicure products.

Structure of reusable nail files and BAF:

- reduces the quality of sterilization;

- does not tolerate disinfectants and ultrasound;

- wears out quickly.

Disposable saw sets or individual tools are thrown away after use. There is therefore no risk of infection transmission and no costs for sterilization.

Manicurists advise using replaceable Smart abrasives for metal media. Discs or strips are discarded and the base is sterilized.

Step-by-step instructions for disinfecting manicure tools

Please note that disinfection of manicure instruments is carried out immediately after completion of the procedure. They cannot be washed with water, wiped, or brushed off anything with a brush, so that skin residues and other particles or components do not rise into the air or splash with running water on you and in the room.

The disinfection procedure is carried out in 3 successive stages:

- All tools are disassembled and untwisted

- Placed in a pre-prepared bath or disinfection unit with the selected solution

- The time recommended for disinfection with each specific solution is maintained.

The liquid must cover the instruments to 2 cm above them for proper processing. Any manipulations with disinfectant solutions are carried out wearing protective gloves. For practical use and economy, it is better to choose a disinfectant that can also be used for pre-sterilization cleaning. She is the next stage.

Pre-sterilization cleaning of manicure instruments - the second stage of processing

After the period of exposure of the instrument to the disinfectant has expired, it is removed from the solution and cleaned using regular or brass brushes, as well as cotton pads under running water for 10 minutes. Not only dirt and small particles are washed away, but also the disinfectant itself, which damages the instruments with prolonged exposure.

The recommended washing time can vary from 1 to 10 minutes, see the instructions for the drug. After cleaning instruments under running water, it is recommended to place them in distilled water for a minute to neutralize any remaining disinfectant solution.

The first and second stages can be combined in two cases:

- Chemical disinfection and cleaning, where a disinfectant solution simultaneously dissolves dirt and particles. All that remains is to rinse everything and dry it before sterilization.

- Disinfection and cleaning in an ultrasonic cleaner. The combined effect of the solution and vibrations allows you to fully prepare the instruments for sterilization. After exposure, we also rinse everything with running water.

Disinfection and pre-sterilization cleaning of manicure instruments: how to choose a disinfectant and prepare the solution correctly

Home sterilizer

Another way to disinfect manicure tools at home? If you have the financial means, you can purchase a special device that disinfects devices. A small container with a hermetically sealed lid affects bacteria with ultraviolet light. There are also devices that perform disinfection with hot steam.

Sterilization of manicure instruments - the third stage of processing

The purpose of sterilization is the complete removal of all microflora remaining after the previous stages of processing.

There are several options for sterilization - thermal, chemical, steam, quartz. According to SanPiN, temperature and pressure treatment in a dry-heat oven, autoclave or infrared sterilizer are considered the most effective.

For commercial purposes, only sterilizers that have a registration certificate from Roszdravnadzor are allowed to be used in beauty and manicure salons. This applies to sterilizers of any type.

A sterilizer that has such a certificate is included in the State Register of Medical Devices of the Federal Service for Surveillance in Healthcare. You can check the availability of any sterilizer in this register on the Roszdravnadzor website. Be sure to check sterilization equipment before purchasing.

Here we have described which dry roasts have a registration certificate and which do not.

How to sterilize manicure instruments in a dry heat oven

Dry instruments, after disinfection and thorough cleaning, are placed in special craft bags with color indicators and then sent to the cabinet. If there are no craft bags, you can unfold the tools with tweezers. Sterilization occurs due to exposure to high temperature, from 121 to 180 ° C for 30 minutes.

This sterilization option is also suitable for processing cutters used in hardware manicure.

How to sterilize instruments in an autoclave

The installation is more expensive than a dry-heat oven and is suitable for large salons or clinics. Sterilization occurs due to exposure to steam and high temperature from 121 to 137 ° C under a pressure of 1.5-2 atmospheres. Lasts 20-30 minutes. Distilled water is used.

The full cycle of operation of the autoclave includes: heating-sterilization, cooling of the instrument. The whole process will take about 50-55 minutes.

The advantage of an autoclave is the ability to process any products and manicure tools. Compared to a dry-heat oven, a number of materials that are destroyed by high temperatures cannot be placed in it.

For autoclave processing, paper or plastic bags are used. Plastic ones are transparent, cost a little more, but keep the instrument sterile longer.

According to SES standards, when sterilizing with an autoclave, a sterilization quality log must be kept. To fill it, test strips are purchased, which are placed on bags or inside bags with instruments during each sterilization. After the processing cycle, stickers with color indicators about the quality of the procedure are transferred to the journal.

How to keep logs of quality control of PSO and concentrations of working solutions according to SanPiN

According to the European standard, autoclaves are divided into 3 classes:

- Class N

- Class S

- Class B

Category N devices are not recommended for nail salons, as packaging cannot be used in them. They process all-metal objects without planes and channels, as well as fabric. These models do not have preliminary vacuumization and drying, so the bags turn out wet after sterilization. There can be no question of any further storage of wet Kraft bags.

Autoclaves of categories S and B can be used for work in a salon or nail salon. They provide vacuumization and drying, and you can process tools in bags.

The full cycle of operation of the autoclave includes: heating-sterilization, cooling of the instrument. The whole process will take about 50-55 minutes.

Autoclave - features, choice and operating rules

Infrared sterilizer

There are only two models of infrared sterilizers approved by Roszdravnadzor on the market:

- ST-IK RELMA;

- ST-IK MAI.

The price of each is about 50,000 rubles. Processing in devices occurs under the influence of a temperature of about 200 degrees, but since this is infrared radiation, the metal does not deteriorate.

ST -IK RELMA provides packaging. It is reusable and expensive. Also included is a stand for cutters.

Processing is extremely fast: 10 minutes for packaged and 6 minutes for unwrapped instruments. The packaging remains sterile for 1 day.

For the infrared sterilizer, it is also necessary to maintain a Quality Log. 1st class indicators are glued to the bags. They connect the packaging lid to the main part. One indicator is enough for one.

There are also 5th class indicators for infrared sterilizers. They are inserted directly into the packaging, and after processing they are pasted into the magazine.

Choosing an infrared sterilizer - review of models

for the ST-IK MAI . Instruments are processed open and must then be used immediately or stored in sterile boxes, a sterile cabinet or a UV sterilizer.

Chemical sterilization

A method carried out using special solutions. Must be performed under sterile conditions using sterile containers, rags, and tweezers for contact with instruments. Conditions must be created for further sterile storage. The result is valid for 3 days. It is not always effective in everyday life in nail salons, however, it is the best backup option if all conditions of the procedure are met.

Chemical sterilization of manicure instruments: rules according to SanPiN

Quartz, ball or glasperlene sterilizer

It has both pros and cons. Pros:

- rapid sterilization under high temperature, takes 20 seconds

- mobility – convenient to use by one specialist in the salon, at home and on the road

- possibility of sterilization of cutters for hardware manicure.

Minuses:

- incomplete immersion of the instrument into the treatment area (balls), and as a consequence the risk of re-spread of pathogenic microflora

- The operating temperature of the device does not always correspond to the declared one, which leads to incomplete sterilization

- the need to replace balls every six months, which many craftsmen are not aware of

- rapid wear of cutting parts due to frequent contact with hard balls.

Properties of glasperlene sterilizer and rating of the best

- Ultrasonic sterilizer , despite its name, is intended for the first two stages - disinfection and pre-sterilization cleaning.

- The ultraviolet sterilizer is intended only for storing already sterilized instruments.

Advantages and disadvantages

Analyzing the advantages and disadvantages of this method of processing manicure equipment, it is worth first of all taking into account that it is additional, alternative, and is designed to solve the problem of sterilization in case of impossibility of processing by other recommended methods.

Advantages of chemical sterilization:

- Suitable for beginner craftsmen at the start, without the budget for a dry heat or autoclave;

- The ability to avoid exposure to high temperatures when processing metals, plastics and rubber;

- The procedure can be carried out decentralized.

Minuses:

- Long exposure time for a number of drugs;

- Short shelf life of processed parts;

- High price;

- Impossibility of processing in packaging;

- The need to equip a special room;

- Toxicity for clients and salon staff;

- Inability to control the quality and effectiveness of the procedure;

- The need to use distilled water for double washing of the solution.

Processing of manicure instruments according to SanPiN

To sterilize instruments in a nail salon, you can use several types of sterilizers, which are permitted according to SanPiN 2.1.2.2631-10, SanPiN 2.1.3.2630-10:

- Dry heat cabinet

- Infrared sterilizer

- Autoclave

- Glasperlene sterilizer

To store already sterilized open instruments, you can use a UV sterilizer; they will remain there for up to 3 days; then it is recommended to repeat the procedure. Manicure tools are placed in it open on perforated trays. According to SanPiN standards, manipulations are performed with gloves.

Clause 9.22 of the SanPiN standards for a nail salon or office requires sterilization and storage of consumables and instruments in sterilization packaging materials or craft bags. If sterilization is performed without packaging, then the instruments should be reused within an hour or stored on special perforated trays in closed UV sterilizers for up to 3 days.

An ultrasonic sterilizer is used to clean and disinfect instruments after a manicure or pedicure. After ultrasonic cleaning, the instruments must dry and undergo heat treatment in an autoclave or dry-heat oven.

The sterilization procedure according to SanPiN takes place in three stages prescribed by the SES:

- After performing a manicure or pedicure, all instruments are soaked in a disinfectant solution in accordance with the exposure time and concentration recommended by SanPin.

- After disinfection, instruments undergo pre-sterilization mechanical cleaning under running water using brushes or brushes, depending on the hardness of the surface being treated. Processing time under running water is from 2 to 10 minutes. This is necessary in order to remove not only the remaining protein particles on the surface, but also to thoroughly rinse off the disinfectant solution, which can cause corrosion during further sterilization at high temperatures.

Pre-sterilization cleaning can be carried out together with disinfection using a mechanized method using a device, for example, an ultrasonic cleaner.A removable tray with a disinfectant solution is placed inside the device, the instruments are immersed, and the recommended treatment time is set for each specific model. On average it is 2-10 minutes.

- Sterilization in a dry-heat oven or autoclave is performed for dry instruments that have undergone disinfection and pre-sterilization cleaning. They are laid out on special trays and placed in a cabinet or autoclave for the recommended time. It is set depending on the selected temperature and can vary from 20 to 90 minutes.

More detailed information on sterilization standards for nail salons and offices can be found in the documents that can be downloaded:

New sanitary and epidemiological rules SP 2.1.3678-20 from January 1, 2022:

- SP 2.1.3.2630-10

What has changed in SanPiN since 2022 >>

Learn more about the requirements of SanPiN and SES standards for the manicure salon in general, as well as for nail technicians.

Clause 9.21 also prescribes the need for at least three standard manicure sets per master’s workplace. This is necessary in order to ensure uninterrupted disinfection and sterilization with a dense flow of clients. The standard set is approved for each salon individually by the administration of the institution. The administration must also appoint an employee responsible for disinfection and sterilization who has undergone preliminary training. This is stated in paragraph 9.26 of SanPiN 2.1.2.2631-10.

Dry-heat cabinet: processing and sterilization of instruments according to SanPiN

Sukhozhar, along with a glasperlene sterilizer, are the most popular devices for sterilizing manicure instruments in salons and by craftsmen at home.

A dry-heat cabinet is an electrical device that exposes a manicure tool to high temperatures - from 160 to 220°C. Depending on the set temperature, the exposure time to dry air also changes. At 180-220°C – 30 minutes, at 170-180°C – 90 minutes, and at 160-170°C – 150 minutes.

These data may vary slightly from model to model, so you should read the instructions before using the device. There are also temporary SanPiN standards for different types of material and tools.

It is important to consider the time it takes to warm up the cabinet itself to the desired temperature. It can last from 5 to 10 minutes, and then the sterilization time begins to count down. On many models this is indicated by a colored indicator light.

The processing algorithm in a dry-heat oven is as follows:

- The instruments are placed in a tray or tray and sent to the chamber. When using Kraft bags, they are first packaged in bags and then placed on a tray or tray;

- Close the lid and set the processing time and temperature;

- After completing the procedure and turning it off, it is necessary to allow time to cool down, and then remove the sterilized material and place it in storage or reuse it.

Only parts made of heat-resistant metal that can withstand temperatures from 180 to 220°C are sterilized in a dryer and autoclave.

According to SanPiN standards, a dry-heat oven, like other types of sterilizers, must be certified for use in Russia, have a passport, instructions in Russian and a maintenance guarantee. Only models approved by the Ministry of Health are allowed for use in the salon.

It is mandatory to have a purchase and sale agreement for equipment and an invoice.

The average device has dimensions of no more than 45 cm. According to SES standards, it must be installed on a flat surface with a distance of 8 cm from the front edge, 10 cm from the back wall with the electrical wire and on the sides, and 30 cm from the top. It is not necessary to allocate space for a dry heat special table.

Sukhozhar - types, choice, use of a sterilizer

Rating of dry heat sterilizers

How to sterilize cutters

Hardware manicure is not as traumatic as a classic edged one, and more effective than an unedged European one. It is impossible to perform it without special equipment, as well as a set of replaceable cutters. With their help, you can quickly remove old coating, get rid of cuticles and rough skin. They must be removed and sterilized after each client. They are made from heat-resistant ceramics or corundum, so they are not afraid of high temperatures. On the sterilizer, you should select the appropriate degrees and processing time. Modern devices are equipped with a user-friendly interface and ready-made modes, including for cutters.